Browse Challenging Surface: Why Picking the Right Undercarriage Parts Issues

Browse Challenging Surface: Why Picking the Right Undercarriage Parts Issues

Blog Article

Optimize Performance With Resilient Undercarriage Parts

In the world of hefty machinery and tools, the function of undercarriage parts is paramount in making certain optimal efficiency and longevity. The effectiveness and performance of these parts can substantially influence the overall operation of equipment, making the choice of resilient undercarriage components an important choice for supervisors and operators alike. By discovering the elaborate connection in between toughness and efficiency in undercarriage components, a deeper understanding of the subject arises, clarifying the critical aspects that drive functional success. As we browse through the complexities of undercarriage upkeep, component, and durability option, an extensive expedition waits for to introduce the essential strategies for achieving peak performance in heavy-duty applications.

Benefits of Using Resilient Undercarriage Parts

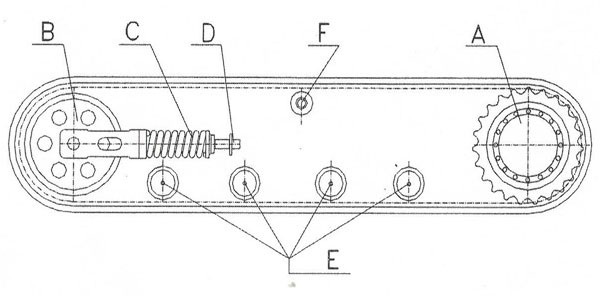

Using durable undercarriage components not just improves the long life of hefty machinery but also minimizes upkeep expenses substantially. By buying high-grade undercarriage parts, such as tracks, idlers, gears, and rollers, tools operators can experience boosted uptime and enhanced overall efficiency.

In addition, the durability of heavy equipment is directly linked to the quality of its undercarriage components. Sturdy components can endure the rigors of requiring applications, making certain that the tools remains operational for extensive periods. Therefore, operators can prevent costly downtime and maintenance expenditures, ultimately making the most of the roi for their machinery.

Factors Impacting Undercarriage Toughness

The resilience of undercarriage parts in heavy machinery is affected by various crucial elements that directly impact performance and long life. High-quality materials, such as solidified steel, are essential for standing up to the extreme conditions and hefty lots that undercarriage parts are subjected to - undercarriage parts.

Furthermore, environmental aspects can have a considerable influence on the durability of undercarriage parts. Exposure to abrasive products, extreme temperatures, and harsh working problems can speed up damage on undercarriage parts. Therefore, picking undercarriage parts that are specifically made to hold up against these environmental obstacles is crucial for making sure toughness.

Furthermore, the layout and engineering of undercarriage parts have a direct influence on their longevity. Parts that are developed to distribute lots equally, decrease friction, and reduce anxiety focus are most likely to have a longer lifespan - undercarriage parts. By taking into consideration these vital aspects, devices operators can make the most of the toughness and efficiency of their undercarriage elements

Maintenance Tips for Prolonging Undercarriage Life

Executing normal upkeep routines is essential for expanding the life expectancy of undercarriage elements in heavy equipment. Furthermore, guarantee that the undercarriage is effectively lubed according to manufacturer guidelines to lower rubbing and prevent early wear.

Another essential maintenance pointer is to maintain the undercarriage clean from dirt, Check This Out rocks, and particles. Buildup in the undercarriage can increase wear and corrosion, causing costly fixings. Washing the undercarriage after procedure in severe problems is recommended to avoid these issues.

Last but not least, tracking and recording upkeep activities can assist in developing an aggressive upkeep timetable. Maintaining comprehensive documents of examinations, replacements, and repair services can offer beneficial understandings into the undercarriage's condition and performance with time, helping in anticipating and stopping possible failings. By adhering to these maintenance tips carefully, drivers can significantly increase the sturdiness and performance of undercarriage components in hefty equipment.

Selecting the Right Undercarriage Parts

Picking suitable undercarriage parts is vital for maximizing the effectiveness and longevity of hefty equipment. When it comes to picking the right undercarriage elements, there are a number of factors to take into consideration.

Furthermore, considering the high quality and online reputation of the producer is crucial. Selecting reputable brands known for producing long lasting and high-performance undercarriage components can substantially impact the overall performance and long life of the machinery. Guaranteeing that the components are suitable with the machine design and effectively mounted is crucial for optimal performance. By carefully selecting the best undercarriage elements, equipment owners can enhance efficiency, reduce downtime, and expand the lifespan of their hefty equipment.

Study: Boosted Efficiency With Long Lasting Components

Integrating long lasting undercarriage parts has demonstrated considerable enhancements in machinery performance. One instance research entailed a building and construction firm that upgraded its excavator's undercarriage elements to more long lasting choices. The business observed a noteworthy decrease in downtime as a result of undercarriage maintenance, resulting in increased performance and expense savings. The durable components held up against rough working problems, decreasing damage dramatically.

In another circumstances, a mining operation changed the undercarriage parts of its excavator with high-grade, durable choices. This switch brought about an amazing renovation in the bulldozer's ability to move and overall efficiency. The device could navigate challenging terrains extra effectively, resulting in boosted operational effectiveness and decreased gas consumption.

In addition, a logging firm spent in sturdy undercarriage components for its forestry devices. These case studies underscore the tangible advantages of making use of sturdy undercarriage components in enhancing machinery performance and longevity.

Verdict

In final thought, using sturdy undercarriage parts can considerably boost performance and durability of hefty machinery. Instance studies have actually revealed that investing in sturdy undercarriage parts review can lead to enhanced total performance and efficiency in numerous sectors.

The effectiveness and performance of these components can substantially affect the overall procedure of machinery, making the choice of long lasting undercarriage components an important decision for managers and operators alike.Integrating durable undercarriage parts has demonstrated significant enhancements in equipment efficiency. These situation researches highlight the concrete advantages of utilizing resilient undercarriage parts in optimizing equipment efficiency and long life.

In verdict, making use of durable undercarriage parts can considerably enhance efficiency and long life of heavy machinery (undercarriage parts). Case studies have revealed that spending in sturdy undercarriage parts can lead to enhanced news general efficiency and performance in various sectors

Report this page